Why Customizable Banana Roller Manufacturers Matter in Modern Industry

In today’s competitive manufacturing environment, precision, adaptability, and consistency are key to maintaining operational excellence. One component that contributes significantly to smooth production processes—especially in industries involving web materials like plastic film, textiles, paper, and foil—is the banana roller. Specifically, the demand for Customizable Banana Roller manufacturers has grown as production lines require tailored solutions to optimize efficiency and reduce waste.

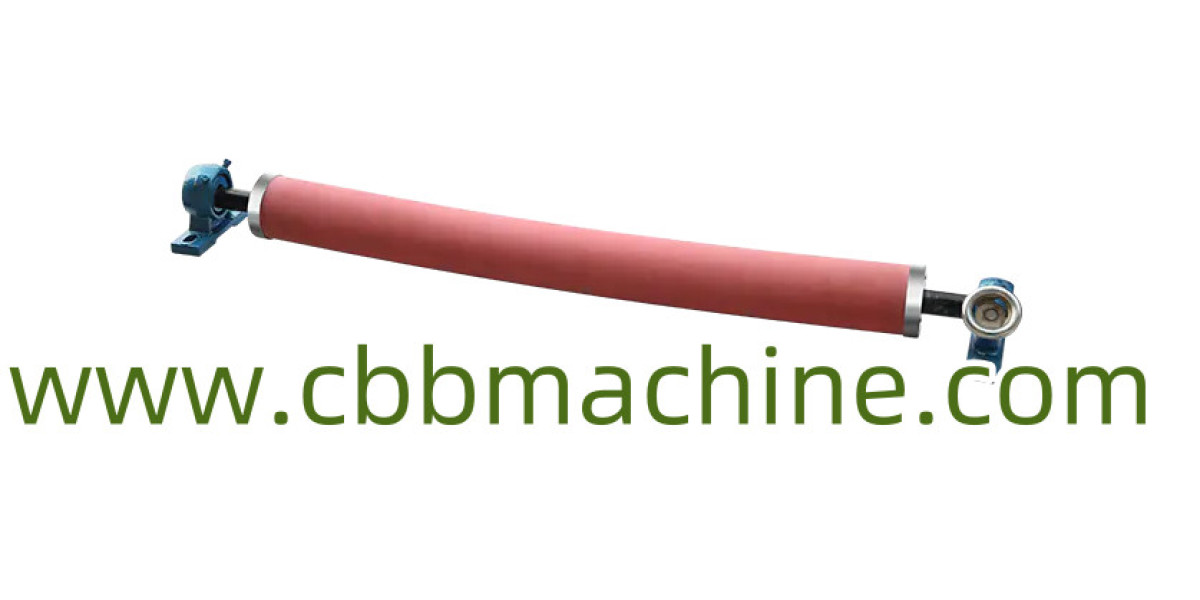

Understanding the Banana Roller

Banana rollers, also known as bowed rollers, are engineered with a slight curvature to eliminate wrinkles, control tension, and improve web alignment as materials move through machinery. They are often installed in printing, laminating, slitting, and converting lines where high-speed processing requires the material to remain perfectly aligned.

The primary function of a banana roller is to apply lateral force to a moving web, spreading it evenly without stretching or damaging the material. This curved shape creates a natural path correction mechanism that traditional straight rollers cannot provide. Because no two production lines are identical, the ability to customize these rollers is critical for achieving optimal results.

The Importance of Customization

Customization allows manufacturers to address specific challenges on their production line. From web width and speed to material type and ambient conditions, every detail can influence roller performance. This is why working with Customizable Banana Roller manufacturers is more than a preference—it’s a necessity.

Key Customization Options Include:

Roller Diameter and Length: The size of the roller can be adjusted to match the dimensions of the machinery and the width of the web material.

Bow Angle: Different degrees of curvature help accommodate various tension and wrinkle correction needs.

Surface Material: Depending on the application, rollers can be coated with rubber, chrome, or other materials to improve grip or reduce static.

Mounting and Bearings: The roller’s internal components can be tailored for high-speed operations, minimal vibration, and easy maintenance.

Each of these features plays a role in ensuring the roller’s performance aligns with specific industrial requirements.

Advantages of Working with Customizable Banana Roller Manufacturers

1. Improved Web Control

Custom rollers help eliminate issues like creases, folds, or web wandering. By designing a roller suited to your material and line speed, Customizable Banana Roller manufacturers ensure stable operation and consistent product output.

2. Long-Term Cost Savings

Although custom solutions might have a higher initial investment, they often lead to long-term savings. Fewer production stops, reduced material waste, and less wear-and-tear on machinery translate to better ROI.

3. Compatibility with Complex Machinery

Modern production lines often involve multiple synchronized machines. Customizable rollers ensure seamless integration and alignment with existing systems, reducing the need for additional modifications.

4. Adaptation to Changing Needs

Production lines may evolve with time—whether due to new product requirements, changes in material, or upgrades in speed and capacity. Customizable Banana Roller manufacturers can adapt roller specifications to accommodate these shifts, offering long-term flexibility.

5. Enhanced Product Quality

Maintaining consistent tension and alignment directly contributes to the final product's appearance and performance. Whether you're producing packaging film or technical textiles, the quality delivered by a tailored banana roller is noticeably higher.

Key Industries That Rely on Custom Solutions

Several industries benefit from working closely with Customizable Banana Roller manufacturers:

Textile Industry: Prevents edge curling and wrinkle formation on delicate fabrics.

Plastic Film & Packaging: Ensures bubble-free laminating and precise edge alignment.

Paper & Label Production: Maintains even surface pressure to avoid tearing or overlap.

Flexible Electronics: Requires extremely precise web handling to protect sensitive materials.

Each industry has specific requirements that make off-the-shelf rollers less effective. This is where customization becomes a valuable part of the production strategy.

Choosing the Right Partner

When seeking a supplier, it’s important to look for manufacturers with experience, technical expertise, and a willingness to collaborate on unique requirements. The right Customizable Banana Roller manufacturers will not only deliver a product but also assist with design consultations, installation advice, and after-sales service to ensure long-term performance.

Future Trends in Custom Banana Rollers

With ongoing advances in automation and smart manufacturing, banana rollers are also evolving. Some of the trends influencing Customizable Banana Roller manufacturers include:

Use of Smart Materials: Integration of anti-static or wear-resistant coatings.

Modular Designs: Enabling quick changeover between roller types or setups.

Sensor Integration: For real-time monitoring of tension, alignment, and wear.

Staying updated with these developments helps industries remain competitive and agile in a fast-changing production landscape.

Conclusion

Customizable banana rollers are not merely accessories—they are critical tools that impact the efficiency, accuracy, and quality of your production line. By partnering with reliable Customizable Banana Roller manufacturers, businesses gain access to tailored engineering that meets the specific needs of their operations. Whether you are upgrading your line or designing a new one, customized solutions will give you the edge needed to maintain precision and productivity.