Exploring the Role of Banana Rollers in Modern Industrial Applications

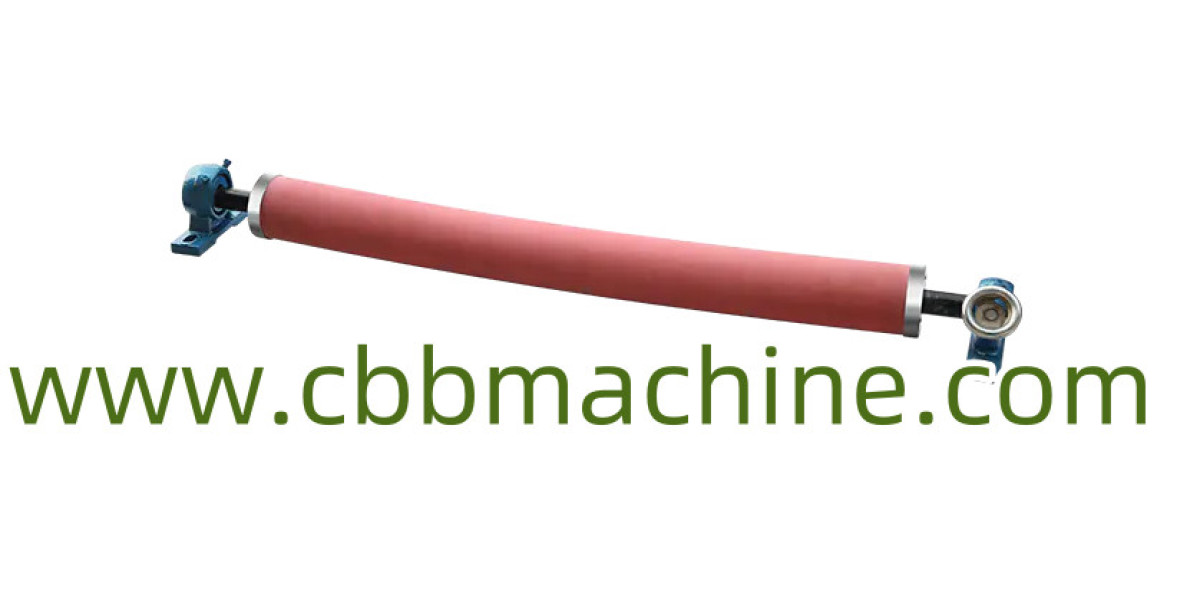

Banana rollers are a critical component in various industries that handle flexible materials. Known for their curved shape and specialized design, Banana Rollers help eliminate wrinkles, maintain tension, and improve material alignment during production. Whether used in film manufacturing, textiles, paper processing, or packaging, banana rollers offer a practical solution to common web-handling challenges.

What Are Banana Rollers?

Banana rollers, also referred to as bowed rollers or spreader rolls, are engineered with a pre-set curvature that enables them to stretch the material evenly across its width. Unlike standard rollers that may allow creases or slack to form in the center or edges of the web, banana rollers use their curved geometry to exert a gentle spreading action. This makes them ideal for preventing overlaps, folds, and tension inconsistencies during high-speed processing.

Made from materials such as stainless steel, aluminum, or rubber-coated metal, banana rollers can be customized in diameter, arc length, and coating to suit various production environments and material types.

Why Banana Rollers Matter in Production Lines

When operating in industries where continuous web materials are involved—such as plastic films, nonwovens, textiles, or foil—problems like edge curling, creasing, and slack can disrupt production quality. Banana rollers play a significant role by reducing such risks.

Here are some of the key functions banana rollers perform:

Spreading folded or wrinkled material to improve flatness

Maintaining consistent web tension across the roll width

Aligning material paths to ensure accurate tracking

Preventing overlaps or misfeeds that could cause defects

Improving output quality by reducing rejects and rework

Banana rollers are typically installed in unwind or rewind stations, slitter machines, lamination lines, and coating systems—making them a versatile tool for engineers and plant managers alike.

Customization Options for Banana Rollers

At CBB Machinery, banana rollers are available in a variety of configurations to accommodate different industrial applications. Key customization options include:

Roller diameter and arc length to match your web width

Surface coating such as rubber, chrome, or anodized aluminum

Material type including lightweight options for reduced inertia

Mounting systems suitable for your specific equipment

By adapting the banana roller to your specific needs, you can enhance production efficiency, reduce downtime, and ensure more uniform processing results.

How to Integrate Banana Rollers into Existing Systems

Integrating banana rollers into your current processing line doesn’t necessarily require a full system overhaul. Many models are designed to retrofit existing machines and can be mounted on standard supports or with adjustable brackets.

During installation, it’s essential to position the roller correctly to maximize the spreading effect. The roller should be oriented with the bow facing the web path, and the contact point adjusted to avoid excessive pressure, which can distort the material.

Conclusion

Banana rollers are a highly practical tool in web handling systems, offering consistent tension control and wrinkle elimination for a wide range of materials. Their customizable features and wide applicability make them a reliable choice for manufacturers aiming to improve operational quality without complicating production processes. Whether you’re involved in flexible packaging, printing, nonwovens, or film processing, banana rollers provide a dependable solution.

To learn more about customizable banana rollers and explore technical specifications, visit: